Professional metal name plate manufacturer in China since 2006. DongGuan YongFu Hardware Co., LTD

Email: kelly.jiang@yfnameplate.com

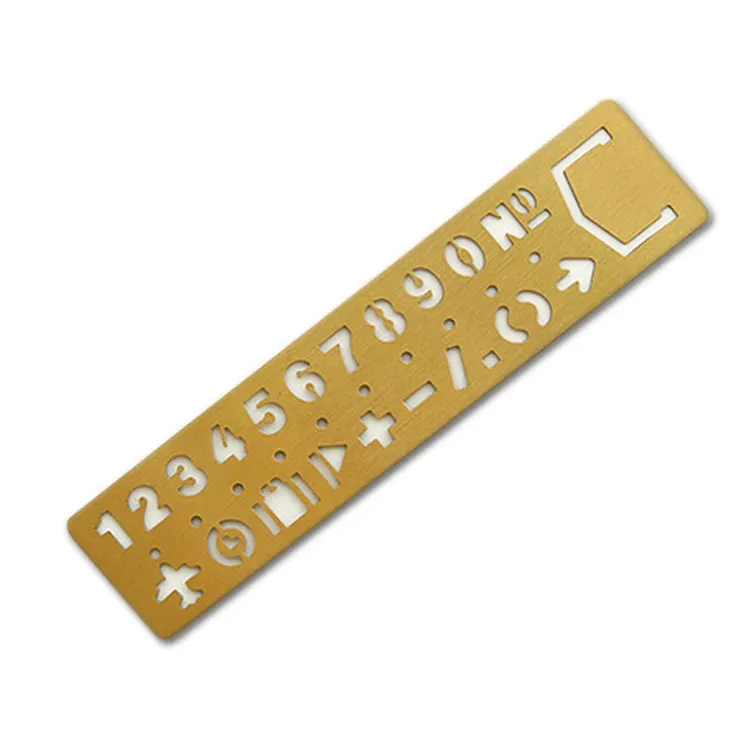

What is the Manufacturing Process of Metal Stencils?

Materials must be carefully chosen to ensure the quality of the metal stencils. The most commonly used material is stainless steel, prized for its durability and resistance to corrosion. However, other materials such as aluminum, copper, and nickel may also be employed depending on specific application requirements.

Manufacturing Process of Metal Stencils

The process of manufacturing metal stencils involves several intricate steps.

Design

The initial step is designing the stencil. This is achieved using specialized software that considers the dimensions and specifications of the PCB. Upon completion, the design is forwarded to the manufacturer for production.

Cutting

The stencil is then cut from the metal sheet using a laser cutting machine. This process ensures precise dimensions and aligns the stencil with the required specifications.

Etching

Following the cutting phase, the stencil is etched to create the necessary openings for the solder paste. This involves submerging the stencil in an etchant solution, which selectively dissolves the metal to form the required openings.

Cleaning

After etching, the stencil undergoes a thorough cleaning to remove any residual material or contaminants. High-pressure water jets or chemical solutions are typically used to achieve this.

Inspection

The final and crucial step is inspecting the stencil to verify its compliance with specified standards. This inspection utilizes specialized equipment capable of measuring the stencil's dimensions, thickness, surface finish, and overall durability.

Quality Control Measures

To ensure the quality of metal stencils, stringent quality control measures are implemented throughout the manufacturing process.

Dimensional Accuracy

Exact measurements are vital to ensure the proper application of the solder paste. Dimensions are meticulously checked using specialized measuring tools.

Thickness Consistency

Uneven thickness can lead to inadequate solder paste application. The thickness of the stencil is routinely verified with a thickness gauge to maintain consistency.

Surface Finish

A smooth and defect-free surface is paramount to ensure even solder paste application. Surface finish gauges are employed to achieve and maintain this standard.

Durability Testing

The durability of the stencil must withstand the high temperatures and pressures encountered during manufacturing. A comprehensive durability test is performed to validate its performance under these conditions.

Conclusion

The manufacturing process of metal stencils is a highly specialized and controlled procedure that demands precision and expertise. Proper material selection, careful execution of each step, and rigorous quality control measures are essential to ensure that the final product meets the required specifications and is suitable for use in PCB manufacturing.

CONTACT US

Contact Person: Kelly Jiang

Fixed Line: +86-769-26627821

Fax: +86-769-22676697

Whatsapp / Phone: +86 139-2921-2779

Email: kelly.jiang@yfnameplate.com

Address: No. 46, Zhouwu Wenzhou Road, Dongcheng District, Dongguan City, Guangdong Province, China

BETTER TOUCH, BETTER BUSINESS.

Contact sales at YongFu Hardware.

Call Us

+86-13929212779